CARBON FIBRE FEVER

Low weight, high stiffness, great strength and eye-catching design are the obvious reasons for the continuing growth of carbon fibre usage in the motorcycle industry. One of the most important parts to significantly improve a motorcycle’s overall performance – from handling, breaking to acceleration – are carbon fibre wheels. With the industries first 3 component composite (carbon-epoxy-steel) and its unique one-piece hollow carbon cast construction, Rotobox is redefining the quality and manufacturing standards of a whole industry. This puts us on the forefront of carbon fiber motorcycle wheel innovations.

Revolutionary

3 component composite

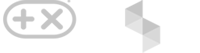

HIGH PRESSURE CORE

The new technology achieves a high density of armature in the composite, extreme metric accuracy and a greater smoothness of the wheel surface. In addition – the wheel becomes watertight.

Thanks to the High Pressure Core Technology the structural rib is placed in the inner side between the spokes, with its mission to support the stress hot spot of the wheel. As a result the BOOST elegant spoke design brings greater stiffness and although the spokes are thinner the BOOST is stronger than ever – with a permissible static load of 280 kg on the rear and 180kg on the front wheel

We can’t reinvent the wheel, but we can give it a new spin

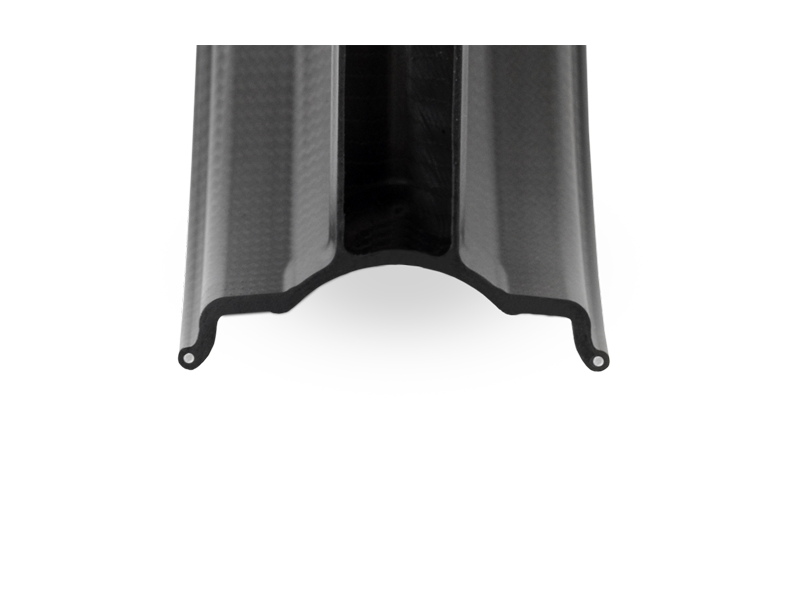

ONE-PIECE HOLLOW CARBON CAST

Rotobox is the first and still the only carbon fibre motorcycle wheel producer in the world to develop and use a unique 3 component composite – combining carbon, epoxy and steel. As the composite itself the one-piece hollow carbon cast production process is a novelty as well. During production several different types of CNC tailored carbon fabrics are hand placed into the negative forming mould of the high precision aluminium tool. For greater impact resistance a stainless 2,5 mm steel wire is added in each side of the rim. Next the liquid epoxy resin is injected into the sealed and tempered tool under very high pressure. This process of producing the one-piece hollow carbon cast is an adaptation of the special high pressure Resin Transfer Moulding (RTM) technology. Ensuring the continuous quality, safety and accuracy of the production process.

RACETRACK INSPIRED DESIGN

The look of the Rotobox wheels is determined by the company’s philosophy to achieve the highest possible performance and safety with no compromises to popular design guidelines. To maximise the advantages of carbon fibre composite, and simultaneously reduce all known disadvantages, we let the experience and expertise of our professional testing team YART (Yamaha Austria Racing Team) flow into the wheel design. The outcome is a spoke, which meets the rim on a substantially large area.

THE CENTRE PARTS

The hubs are CNC machined from 7075 T6 aluminum alloy, anodized into optional color and permanently assembled to the carbon rim. Designed specifically for each motorcycle model, the Rotobox wheels are a direct replacement of the OEM-wheels and are supplied with a cush drive, sprocket carrier, spacers and a choice of ceramic or steel bearings.

7075 T6 aluminium alloy

TESTING LAB

Because safety is our top priority, we set up an in-house test laboratory to constantly check and improve the quality of our products.

RADIAL FATIGUE TEST

The test aims to confirm the durability of the rims and hubs. For this purpose a drum is rotating the wheel at a constant velocity of 32 km/h while applying the radial load (FW: 3400N / RW: 5600N at min. 500.000 turns).

TORSION FATIGUE TEST

The test aims to confirm the durability of the spokes and hubs. For this purpose the wheel is fixed onto the support, while the torsional moment (FW: 500Nm / RW: 810Nm at min. 100.000 turns) is repeatedly applied through the contact surface of the hub.

CORNERING FATIGUE TEST

The test aims to confirm the durability of rims and hubs. For this purpose the wheel is fixed to a rotary disc, that is able to provide a bending moment (FW: 2500Nm / RW: 410Nm at min. 100.000 turns) to the centre of the wheel, while rotating with a constant velocity.

IMPACT TEST

The test aims to confirm the air retainability of the tires and strength of the rims, spokes and hubs. For this purpose the striker weight (FW: 225kg / RW: 410kg) is dropped on the wheel from a height of 150 mm to apply the impact load.